Products

Here you can explore our in-house developed products, crafted over the years to meet customer needs, as well as the resale products we are proud to offer. 3D metal printing technology opens up endless opportunities — just tell us your requirements, and we will design and manufacture the product you need.

Industrial mixers

for mixing liquid, gas and solid materials

We offer a wide range of agitators designed for different applications. Our most common construction materials are 316L (Wnr. 1.4404) and Hastelloy C22 (Wnr. 2.4602). While liquid mixing is the most typical process covered by our products, many applications also involve liquid–gas, liquid–solid, or even three-phase systems. Based on the properties of the material to be mixed and the size of the vessel, tank, or reactor, we can provide the most suitable solution for the task. To ensure optimal performance, we validate the mixing process using CFD simulations, guaranteeing that our customers receive not just an agitator, but the right tool for their process.

Complete mixer inside of a reactor

Scaled laboratory mixers

Polished, interchangeable Optifoil blade

Complete mixer inside of a reactor

Several DIN reactors ready for field installation, FAT and SAT testing.

TIG welding during manufacturing

3D model of a designed reactor

Several DIN reactors ready for field installation, FAT and SAT testing.

Reactors

for pharma, API, food and chemical industry

A proper agitator requires the right vessel. From simple tanks to advanced reactors with heat exchange, we deliver constructions tailored to customer needs. While standard DIN-size reactors are our core products, we also design fully customized vessels. With standard pipe connections, powder feeding systems, integrated temperature measurement, and temperature control options, we meet the highest process requirements.

Designed with precision and validated through FEA simulations, our vessels guarantee reliable pressure performance.

Temperature Control Unit (TCU)

for processes where heat matters

A TCU (Temperature Control Unit) precisely regulates reactor temperature by circulating heat-transfer fluid through the jacket or other heat-exchange zones. With both heating and cooling capabilities, it ensures optimal process performance, consistent product quality, and faster reaction times — making it indispensable in industries such as pharmaceuticals and fine chemicals.

Our ready to install TCU.

The assembly phase of our Temperature Control Unit.

An appropriately insulated TCU for the best energy efficiency.

Our ready to install TCU.

Repairing cylindrical glass-lined vessel walls with tantalum patches and bolts.

Reactor baffle corroded due to surface damage and acidic or alkaline media

The tightening sequence and applied torque of the screws are critical factors.

Repairing cylindrical glass-lined vessel walls with tantalum patches and bolts.

Tantalum patch

used for glass-lined equipment repair

Tantalum patching is a common method for repairing glass-lined equipment. In the simplest cases, tantalum bolts and a sheet are used; however, when multiple radii need to be covered, the sheet is hammered into shape. If the fit is not precise, the enamel may crack during bolt fastening. To avoid this risk, FLONO applies a more reliable approach: by 3D scanning the corroded area, creating a precise 3D model of the patch, and manufacturing it with advanced 3D printing technology.

The result: a perfectly fitting patch and a longer service life for your equipment.

ROTADEST Flask Heating Unit (RFHU)

for lab processes where GMP matters

Our ROTADEST Flask Heating Unit is engineered to fit each flask with precision, delivering uniform heat across the entire surface. Even in GMP-regulated environments, solvent density challenges are resolved swiftly.

Smart, reliable heating solutions for the most sensitive laboratory processes.

Already manufactured FHU with handy temperature control display.

The easy to use locking mechanism of the Flask Heting Unit.

Space-saving support stand for the FHU.

Already manufactured FHU with handy temperature control display.

A delivered Valve Heting Unit (VHU)

The raw VHU after the 3D metal printing process.

A delivered Valve Heting Unit (VHU)

Valve Heating Unit (VHU)

no more frozen valves

In some processes, low temperatures can cause control valves to stick, potentially leading to dangerous situations. With our solution, you don’t have to worry about this. Heating is provided not electrically, but through an available onsite heating medium such as oil or steam.

Engineered to prevent valve failures and maintain safe processes.

Continous flow reactors

for continous manufacturing processes

Yes, it is officially possible!

Although we have manufactured several unique continous flow reactors, we cannot share any images or concepts of the products due to signed non-disclosure agreements. However, if you are interested, contact us to arrange a meeting — we will work together to create a unique solution tailored to your requirements.

LUMINO GENIE

multifunction sightglass

FLONO Lumino Genie is a sightglass with many functions. Features: 316L, heating integrated for steam or oil, integrated borosilicate insulation, borosilicate sightglass in fused design, DN50, PN40, flanges as per EN1092 Type 11, sizing as per DIN. Integrated LED light from side, two additional side ports for flow switch/temperature measurement/sampling device.

Fully designed in 3D

Heating integrated for steam or oil, integrated borosilicate insulation, borosilicate sightglass

The half section view of Geine in 3D

Fully designed in 3D

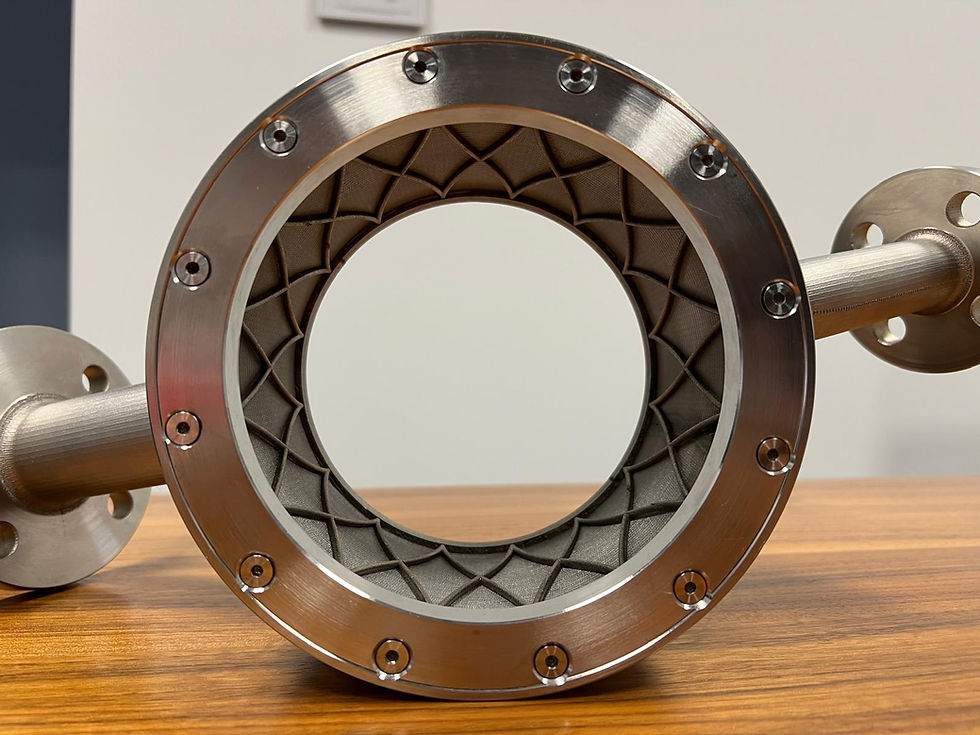

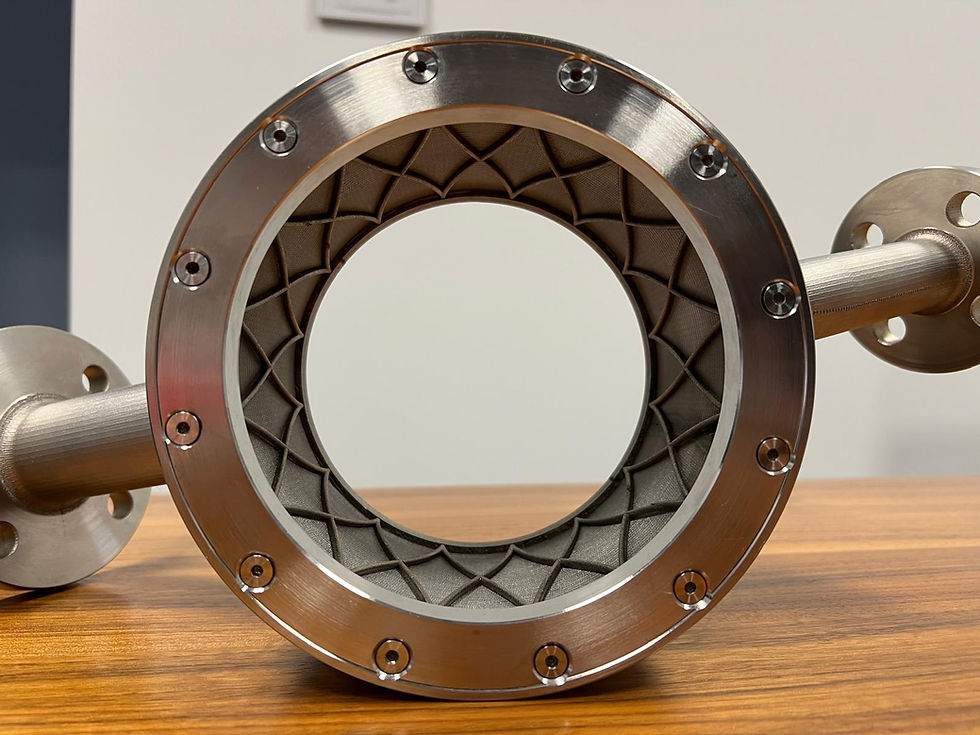

Fine mesh inside the filter unit.

Fully 3D printed except the mesh.

Perfect connection, excellent operation.

Fine mesh inside the filter unit.

Hastelloy mesh filter for reactors

mounted between the reactor and its discharge valve

If you need to filter the discharged product of a reactor, this is the solution. Corrosive, acidic, or alkaline fluids are no problem (within the specified limits) for this Hastelloy C22 mesh filter. It can be easily cleaned using counterflow blowdown. Available in various mesh sizes and pipe connections, tailored to costumer needs.

Your process, perfectly filtered.

CEPIC sales representative

high quality graphite heat exchangers

We are proud to offer CEPIC products as official sales representative, providing reliable and proven solutions for demanding industrial applications. Our main activity is the resale of CEPIC heat exchangers, but we are also happy to assist with their other products. In addition, FLONO Kft. provides servicing for CEPIC heat exchangers in the region, ensuring faster turnaround times and saving on shipping costs — so your equipment can return to operation more quickly.

Anticorrosion since 1958

The first graphite heat exchanger received in our workshop for repair.

side view

Anticorrosion since 1958

Industrial fans for wide range of applications

Available in ATEX version

Industrial fans for wide range of applications

Slingerland Techniek BV product resale

industrial fans designed for a wide range of applications

Our product portfolio is enhanced by industrial fans from Slingerland Techniek BV. Whether for standard or ATEX environments, we provide equipment tailored to your specific requirements. Explore their products at www.slingerlandtechniek.nl/en or on our Hungarian website www.slingerland.hu.

For personalized assistance, feel free to contact our team directly.

Foeth Product sales partner

sustainable industrial solutions, industrial equipment for standard and ATEX environments

FLONO Additive proudly serves as the official Foeth sales partner for Central and Eastern Europe (including Serbia, Romania, Hungary, Czech Republic, Slovakia, and Slovenia). We believe that high-quality, pre-owned process equipment is beneficial for every business – quick, cost-effective, and environmentally responsible.

Browse Foeth’s inventory to find the right equipment for your processes at www.foeth.com/en/our-inventory.

For personalized assistance or to request your individual discount code, contact our team directly.

Logo of Foeth

QVF Glasstechnik S-ROB45/300/SH/3SIC-4,5m² - Shell and tube heat exchanger #industrial heat exchanger #ipari hőcserélő

Collette MPH 300 - Planetary mixer #Bolygóműves keverő

Logo of Foeth